Stress Corrosion Cracking (SCC)

Through experience and published knowledge, it has been widely known in the industry that SCC is a major weakness for type 304/316 austenitic stainless sheets of steel. It is a fact that designers must always consider when specifying the use of the alloy in boilers and heat recovery units.

Therefore, there is a higher risk of SCC existing when the following conditions are present: (a) temperature above 140o F; (b) tensile stresses, and (c) the existence of Chloride ions.

In the engineering design process of thermal systems, K1SCC, residual stress, temperature, alkali presence, and oxygen level in water should be considered for the selection of materials. Certain aluminum alloys, stainless steels, copper alloys, and titanium alloys are susceptible to SCC.

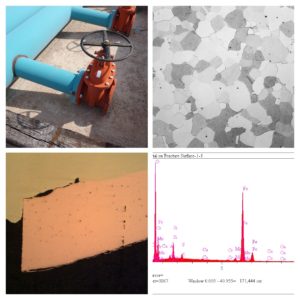

Galvanic Corrosion

Galvanic corrosion occurs when metal parts act as electrochemical cells, whereas anode and cathodes have been formed. Galvanic cells are three types: composition cells, stress cells, and concentration cells. Composition cells are formed when dissimilar metals have been used in manufacturing a product. Different alloys affect the composition of cells on the basis of their ranking to anodic or cathodic tendencies in a particular environment.

Failure Analysis Root Cause Investigation-Our Approach

Once a failure has occurred, the point of origin must be found. Therefore, it must be determined whether the failure occurred as a result of design, a method of manufacturing, service history conditions, soil/water chemistry excursions, or from a deficiency in the material. When the point of origin is located, the investigation proceeds to a study of how the failure occurred, possible causes or factors in the failure, and possible means of preventative measures.

Why a failure occurs is an important question in the method of evaluation. This question can be approached by breaking down the failure into “mode of failure” and “cause of failure.”

- The mode of failure is the process by which the failure occurred.

- The cause of failure is that which can be fixed or changed to prevent future failures.

Each question provides important clues to the investigation, and although priorities may be quite different. The consultants will address each question and resolve the failure to understand why it may have occurred.

Several important factors often associated with component failures are overloading conditions, vibrations, corrosive environments, deficiency in design, fabrication, operating conditions, unsuitable materials selection, and extended useful life.

Our failure analysis procedure, or methodology for evaluation, will be provided in a step by step approach. This includes justification for conducting a failure analysis investigation, developing a logical plan for the investigation to follow, a collection of background information, sample removal techniques, on-site inspection, laboratory testing and analysis, and the formulation of a final report based on relevant data, analysis, and recommendations.

Above all, your input is vital for our failure analysis root cause determination. By giving us a detailed description of the failure, you can be sure that all aspects of failure investigation will be considered promptly.

We’ll send you a proposal for your work/project, including methods, testing, specific recommendation, and costs.